ModSort Modular Conveyor System

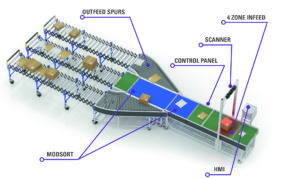

In partnership with ModSort™, we can help you achieve unlimited motion control with a modular conveyor system.

The ModSort station is an innovative low-noise, low voltage modular transfer and diverter station. It can easily integrate with new or existing material handling systems, eliminating the need for a lift, pneumatics, or Z-direction position feedback devices, and can help achieve energy savings from 50-60% when integrated with a motorised roller-based system.

What Does ModSort Do?

- Receives product

- Passes product straight through

- Diverts product left or right

- Can be used to divert in two different modes:

- Stop & divert full 90 degrees

- Divert on the fly (blended vector angle)

![]()

Modular and scaleable Sorter system

Integrated with new or existing MDR conveyor for simple right angle or on the fly diverts

How It Works

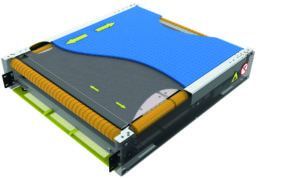

System Plast® 2253 Roller Top belt (blue) is used as a transfer belt to receive and pass product through or, when the divert belt (black) is activated, diverts packages left or right. Both belts are driven by industry standard MDR technology.

_______________________________________________________________________

________________________________________________________________________

Application Considerations

- Package rates of 35-50 per minute

- Typical package sizes less than 30” x 30”

- Weight of 50 lbs or less

ModSort Features

- Easy integration into existing traditional or motorised roller conveyor systems

- Unlimited motion control, energy efficiency/runs on demand technology

- No need for mechanical lift ‘pop-up’ (only two means of motion required)

- Quiet, safe, low maintenance, 24 volt DC

- Utilises unique System Plast™ 2253 Roller Top belt technology

- Low noise and low voltage (24VDC), no conduit required)

- Easy maintenance through minimum spare parts requirements

- High-resolution package control

ModSort Benefits

- Transports a wide variety of products

- Ideal for handling smaller packages without the ‘gaps’ associated with pop-up transfer modules

- Efficiently handles polybags – less damage, no gaps, no catching

- Zero contact, zero pressure accumulation

- Energy savings as high as 50 to 60% compared to traditional conveyor